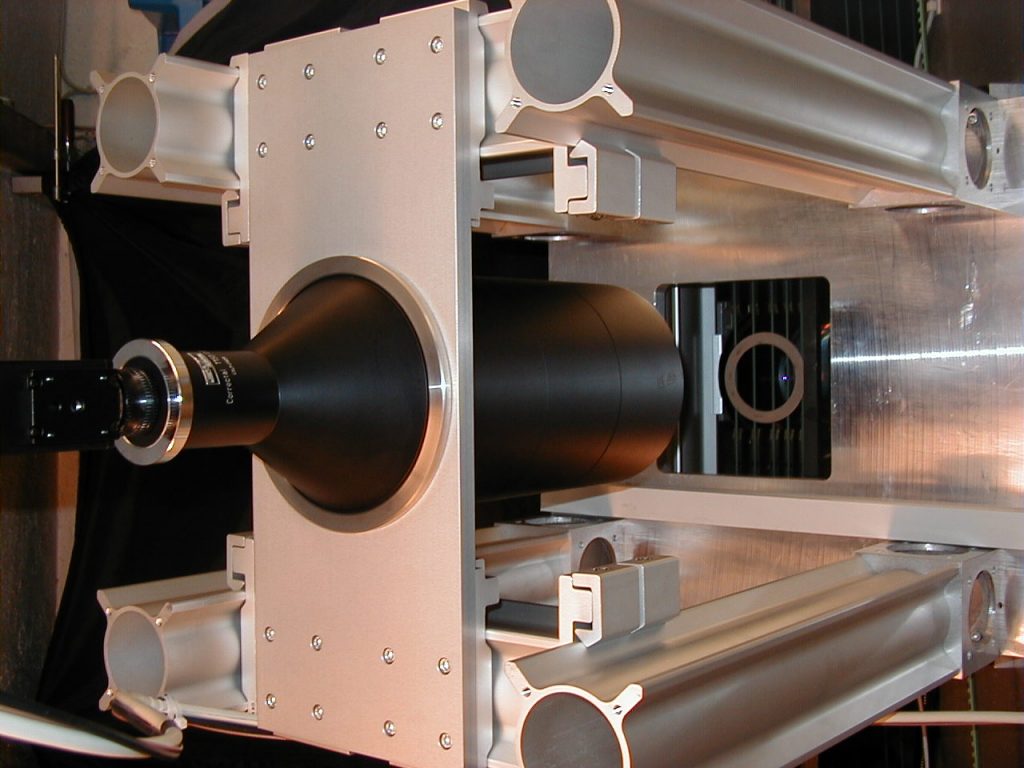

Robiscan® has been around for over 10 years as the leading inline inspection system for defect-free welds with strength and appearance requirements. More than 250 installed systems reliably detect even the smallest defects at well-known premium automotive manufacturers worldwide. In addition, Robiscan provides automatic inline surface inspection on metallic and painted surfaces for even the smallest defects.

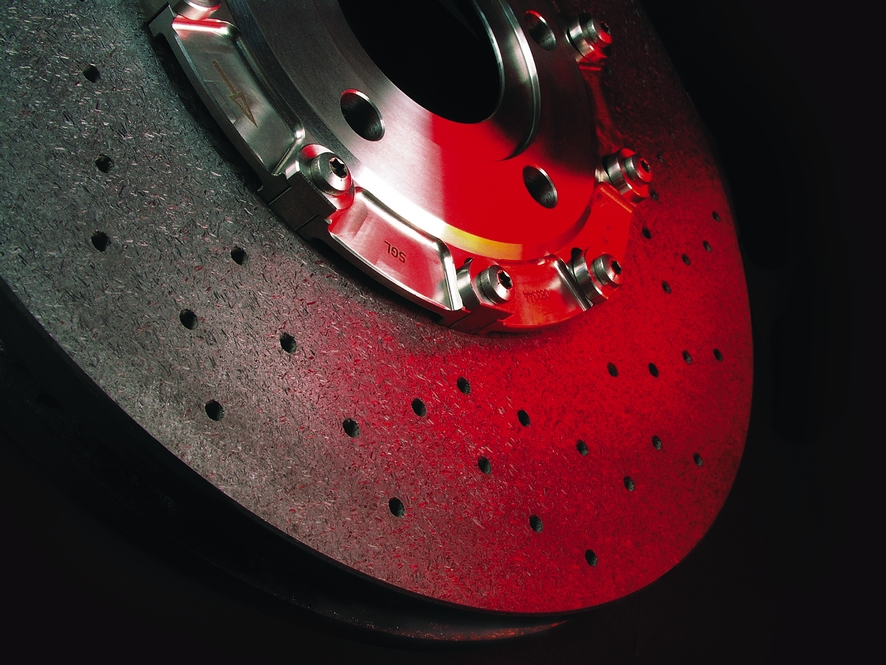

Steelinspect 3D can inspect hot surfaces up to over 1200° C. Steelinspect 3D thus enables surface inspection on continuous castings for the first time. Compared to conventional 2D surface inspections, Steelinspect 3D additionally detects and evaluates the depth of defects in the steel.

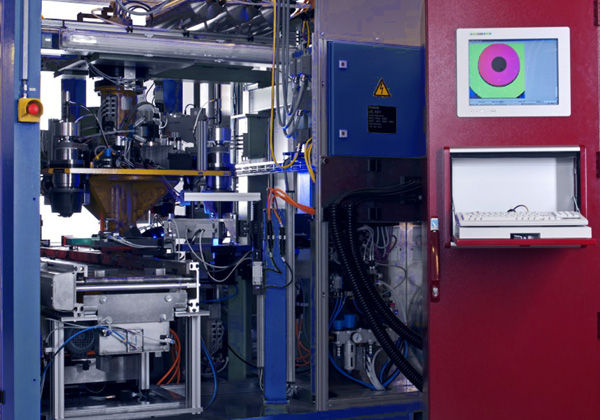

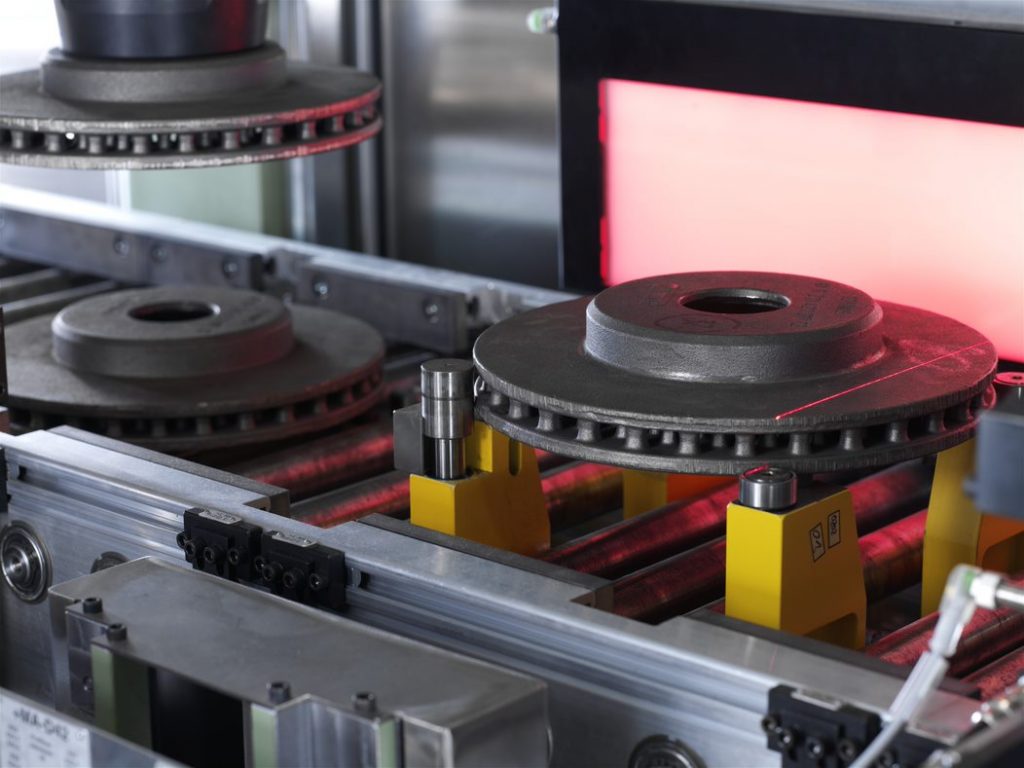

Sensior® is a fully automated test cell that performs automated surface and dimensional inspection for rotationally symmetrical castings.

Surface inspection of flat parts such as sheet metal stampings for scratches, impact marks, scoring, contamination, etc. is faster and more reliable than before with Advic®. Unit costs are reduced, while quality is demonstrably increased. These are critical competitive factors, especially for stamped parts. The system is of course designed for operation in a 3-shift system.

All of our solutions can be combined with Inline 3D measuring. ask us anything One platform – many solutions During the surface inspection, the...

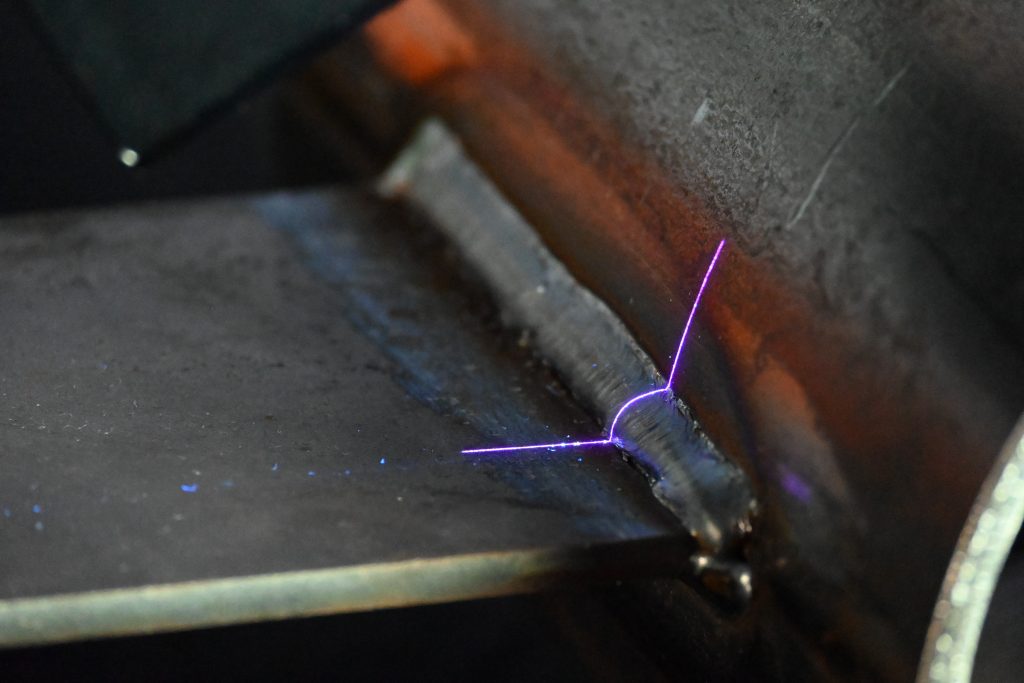

Flatness inspection using the laser light section method allows for accurate, fast and cost-effective testing of flat parts for flatness. Both the cycle time...

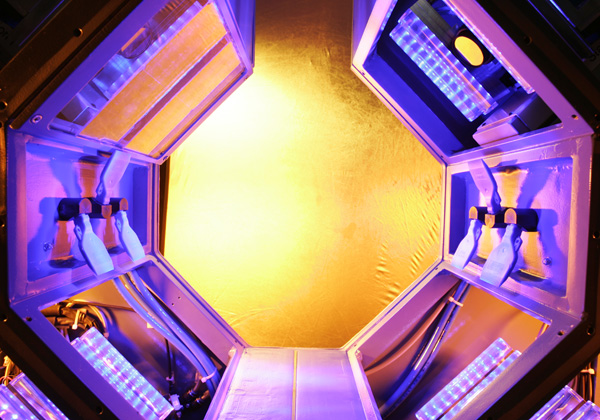

UV radiation is replaced by blue LED light, significantly improving defect detection.