Automation W+R GmbH announces a change in its executive management: Ralph Christoph joins the existing management team, Dr. Richard Söhnchen and Paul Gruber.

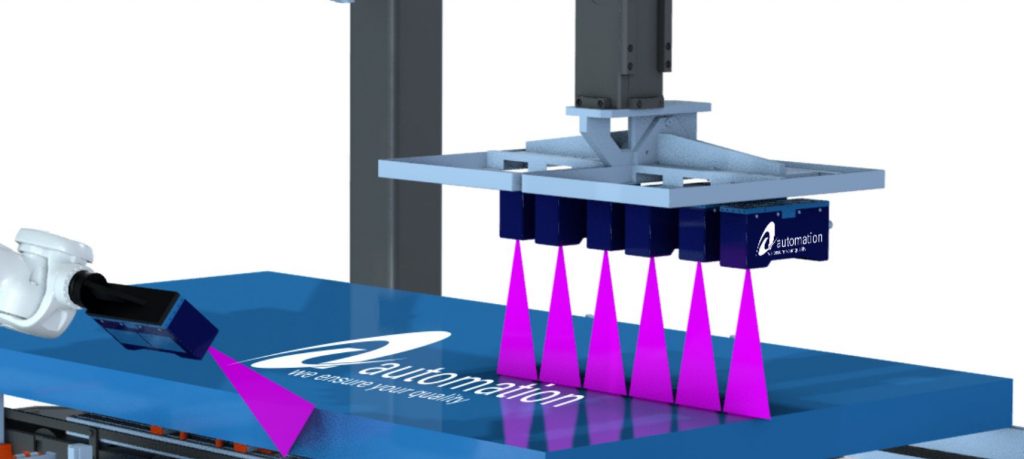

With BATTERYSPECT-3D, Automation W+R is implementing for the first time a fully integrated turnkey solution that combines 100% inline surface inspection and geometric measurement of automotive high-voltage battery systems within a single machine.

Presentation on 2D & 3D seam inspection for high-quality EV batteries. By Michael Wagner from Automation W+R at Battery Systems 2025. The combination of 2D and 3D inspection methods enables significantly more efficient defect detection, better process reliability, and thus higher battery manufacturing quality.

Quality, speed, and efficiency are key in battery and body production. With ROBISCAN®, the leading modular inspection platform for efficient and sustainable quality assurance, the BMW Group and thyssenkrupp Automation Engineering are securing their competitive edge.

The requirements regarding safety and quality of components are constantly increasing, especially in the automotive industry. To meet these challenges, clear, objective, traceable and efficient quality inspection of components is essential. As a solution, Automation W+R has developed an inspection system that takes production processes and product quality to the next level using high-speed 3D inspection. Read more about this in the article in the current issue of PC Control.

Battery Show Europe 2025 – From June 3 to 5, we will be presenting our battery testing systems in Stuttgart. Come and see us! The Battery Show Europe and the Electric & Hybrid Vehicle Technology Expo Europe take place annually at the Stuttgart Exhibition Center. Find out all about e-mobility, future technologies and the latest developments in the battery industry. Visit our stand 4-B50.

We are now a member of the Batterline network! Batteryline.com is a community of experts from the lithium-ion battery cell production industry. The Batterline network stands for innovation and the promotion of cooperation in the battery and energy storage industry.

Automation W+R will participate in EALA 2024 (European Automotive Laser Applications). The Automotive Circle conference, dedicated to the latest developments and applications of laser technology in automotive production, will take place on February 6 and 7, 2024, in Bad Nauheim. Come visit us!

Automation W+R is taking part in EALA 2024 – European Automotive Laser Applications. The Automotive Circle conference will take place on February 6 and 7, 2024 in Bad Nauheim and is dedicated to the latest developments and applications of laser technology in automotive production. Come and visit us.

21.11.2023 – Paul Gruber reported on the topic of AI in practice for Automation W+R GmbH at the meeting of the Committee of Industry, Innovation and…